Introduction to 3 Nozzle 3D Printers

3 nozzle 3D printers represent a significant advancement in additive manufacturing, offering unique capabilities that set them apart from traditional single and dual nozzle printers. The fundamental distinction lies in their ability to extrude material through three distinct nozzles simultaneously or sequentially. This configuration allows for greater versatility in printing complex models, as various materials and colors can be applied in a single print job, enhancing creativity and reducing the need for post-processing.

The technology behind multi-nozzle 3D printing has evolved rapidly, driven by innovations in both hardware and software. Notably, manufacturers have developed advanced algorithms that effectively manage the operation of multiple nozzles. This sophisticated management system ensures that each nozzle is utilized efficiently, optimizing material flow and minimizing the risk of clogs or print failures. Furthermore, advancements in thermoplastic materials have broadened the range of suitable filaments for use in 3 nozzle systems, making them compatible with a wider array of applications.

Incorporating multiple nozzles into a 3D printing setup provides numerous benefits. One of the primary advantages is the ability to print models with varying mechanical properties. For instance, softer, flexible materials can be combined with rigid materials, enabling the creation of parts that exhibit both flexibility and strength. Additionally, the use of multiple colors allows designers to create visually stunning prototypes and products without the need for tedious manual painting. This functionality is particularly advantageous in industries such as product design and engineering, where visual appeal and functional performance are critical.

In conclusion, 3 nozzle 3D printers represent a transformative option for users seeking to maximize efficiency and creativity in their projects. By leveraging the unique capabilities of multiple nozzles, these systems can significantly enhance the additive manufacturing process.

How 3 Nozzle 3D Printers Work

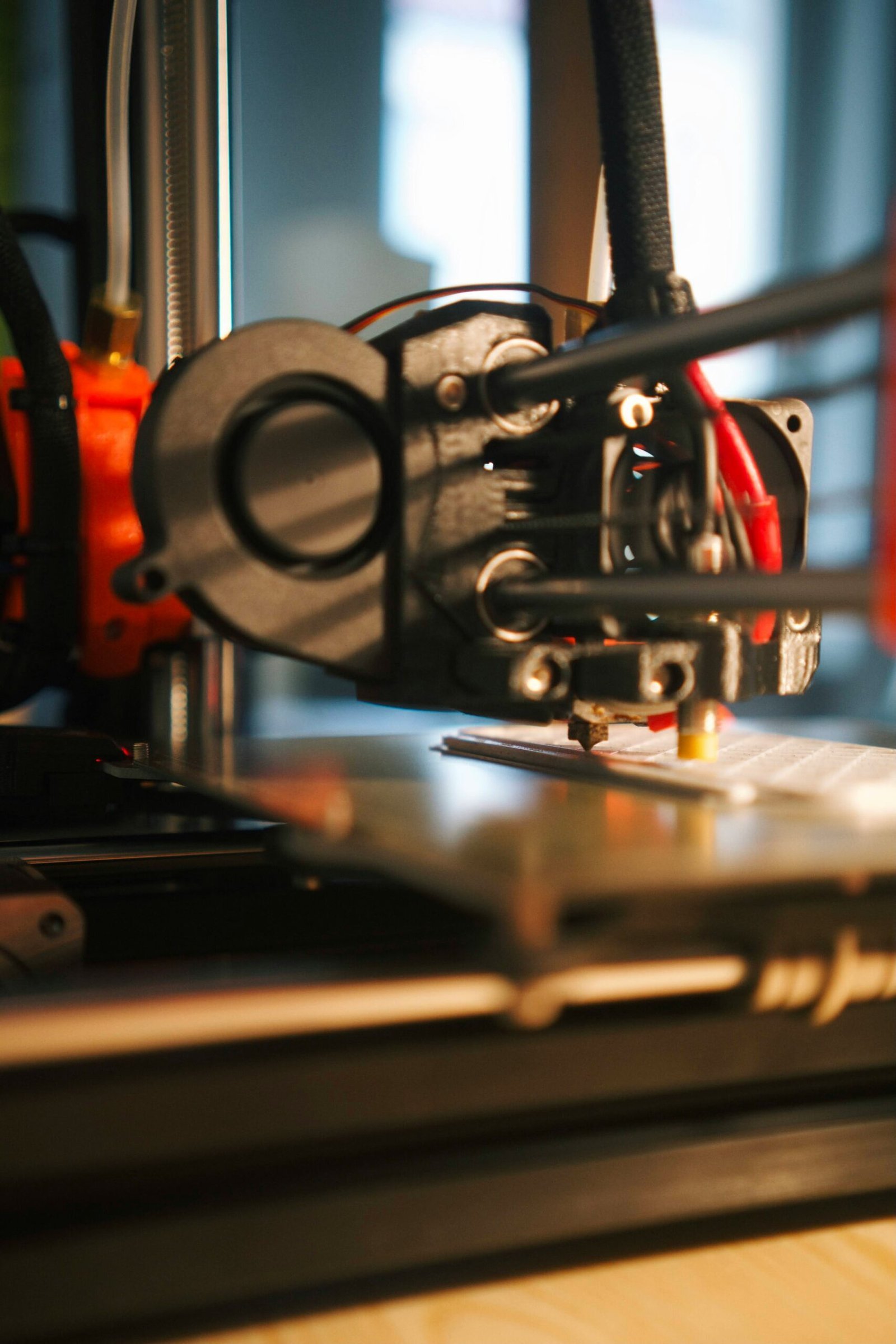

3 nozzle 3D printers are an advanced type of additive manufacturing technology designed to enhance versatility and efficiency in creating three-dimensional objects. Unlike traditional single-nozzle printers, these machines are equipped with three distinct nozzles, which enable them to simultaneously extrude multiple colors or different materials during the printing process. This capability not only allows for more complex designs but also streamlines the workflow by reducing the need for manual color changes and reprints.

The mechanics of a 3 nozzle 3D printer involve a coordinated system where each nozzle is fed by an individual filament spool. The printer’s software plays a crucial role in controlling the movement of these nozzles, ensuring precise timing and synchronization to achieve the desired output. As the print head moves along the x, y, and z axes, it selectively engages the appropriate nozzle based on the color or material required at a given point in the print job.

Each of the three nozzles is typically heated independently, allowing for a variety of filament types to be combined within a single print, such as PLA, ABS, or flexible materials. This feature is particularly beneficial for producing objects with complex geometries, intricate details, or varying material properties, which is a significant advantage over conventional printers.

In terms of internal components, a typical 3 nozzle printer includes a print bed, stepper motors, an extruder assembly, and specialized firmware. The print bed provides a stable surface for the printed object, while stepper motors ensure accurate movement of the print head and bed during the printing process. The extruder assembly is pivotal in drawing filament from the spool, melting it, and depositing it layer by layer to build the final product. The firmware governs the interactions between all components, managing the intricate operations necessary for successful multi-material printing.

Benefits of Using a 3 Nozzle 3D Printer

The advent of 3 nozzle 3D printers has significantly transformed the landscape of additive manufacturing. One of the primary advantages of utilizing a 3 nozzle printer is its enhanced color capabilities. With the ability to print using three different colors simultaneously, designers and hobbyists can achieve vibrant and intricate designs. This feature opens avenues for creating more aesthetic and visually appealing objects, facilitating innovative projects that would be cumbersome with single or dual nozzle printers.

Another notable benefit is the ability to incorporate different materials for various components of a print. This versatility allows for the combination of rigid and flexible materials within a single object. For instance, a designer could produce a model featuring a hard outer shell along with a soft inner core, resulting in functionality that is not achievable through standard printing techniques. This is particularly beneficial in industries like prototyping and manufacturing, where specific parts must have distinct properties.

Moreover, 3 nozzle 3D printers enhance time efficiency, especially when printing complex objects. By integrating multiple materials and colors, the printer can create parts in a single pass, rather than requiring multiple setups or post-processing steps. This capability is crucial for industries that rely on rapid prototyping, as it allows for quicker turnaround times on projects. Real-life applications abound, such as in the automotive and aerospace sectors, where intricate designs are frequently tested and modified. Case studies have demonstrated significant reductions in production times, allowing companies to respond faster to market demands and innovation cycles.

In essence, the utilization of a 3 nozzle 3D printer delivers numerous benefits, including expanded design possibilities, material versatility, and improved production efficiency. As the technology continues to evolve, its integration into various fields is likely to expand further, fostering creativity and operational enhancements.

Choosing the Right 3 Nozzle 3D Printer for Your Needs

When selecting a 3 nozzle 3D printer, there are several key factors to consider that will ultimately influence your printing experience and overall satisfaction. One of the most critical aspects is the build size. It is essential to evaluate the maximum dimensions your projects require, as a larger build size allows for more complex designs and larger prints. Be mindful that a printer’s dimensions may restrict your creativity if they fall short of your needs.

Another factor to consider is the nozzle diameter. Different nozzle sizes will affect the precision and speed of your 3D printing. Smaller nozzles are ideal for detailed prints but may result in longer print times. Conversely, larger nozzles facilitate quicker prints at the cost of intricate detail. Understanding your typical print requirements will help you select the appropriate nozzle diameter suited to your specific projects.

Brand reputation plays an essential role in your decision as well. Established brands often provide better reliability, quality, and customer service, which can greatly enhance your experience. It is advisable to read reviews and examine feedback from other users to gauge the printer’s reliability and the support options available.

Additionally, support options are crucial when considering a 3 nozzle 3D printer. Comprehensive warranty policies and accessible customer support can save time and frustration in case any issues arise during use. Be sure to investigate the manufacturer’s support offerings and community resources that can assist you when troubleshooting.

Lastly, price range is a significant factor. 3 nozzle 3D printers vary widely in cost, and it is important to find a model that fits within your budget while meeting your printing requirements. Assessing all these factors holistically will help you make a well-informed decision tailored to your creative needs.

Best 3 Nozzle 3D Printers on the Market

In the landscape of additive manufacturing, 3 nozzle 3D printers have garnered attention for their ability to enhance printing efficiency and expand creative capabilities. A selection of notable models has emerged, each catering to different preferences and requirements of users. This section examines some of the leading 3 nozzle 3D printers currently available, focusing on their features, technical specifications, pricing, and customer feedback.

One model worth considering is the Prusa i3 MK3S+, renowned for its reliability and exceptional print quality. This printer boasts a modular design that allows users to swap out nozzles easily, making it versatile for various tasks. Its robust community support is supplemented by an extensive library of resources, which aids both novice and experienced users. The Prusa i3 MK3S+ costs around $999, providing excellent value for the features it offers.

Another noteworthy option is the Raise3D Pro2, distinguished by its large build volume and dual extrusion capabilities, ideal for high-quality multi-material prints. This printer is equipped with a fully enclosed build chamber, ensuring temperature stability, which is crucial when working with advanced filaments. The Pro2 is priced higher at approximately $3,999, reflecting its professional-grade performance and extensive capabilities.

For budget-conscious users, the Anycubic Chiron presents a more affordable alternative without sacrificing essential features. This large-format 3D printer supports various filament types and offers a competitive price point of about $499, making it a popular choice among hobbyists and educators. While it may not have all the sophisticated features of pricier models, user feedback highlights its ease of use and solid print quality.

Lastly, the LulzBot TAZ Workhorse impressively combines reliability with a spacious build volume. Its open-source design fosters greater freedom in material usage and hardware modifications, appealing to makers and DIY enthusiasts. Priced at around $2,500, it competes well in the mid-range market, garnering positive reviews for its user-friendliness and consistent performance.

Maintenance Tips for 3 Nozzle 3D Printers

Maintaining a 3 nozzle 3D printer is crucial for ensuring optimal performance and longevity. Routine care helps to prevent issues such as clogs or jams, which can disrupt the printing process. Proper cleaning and nozzle care are essential components of maintenance. First and foremost, regularly inspect and clean the nozzles. Accumulation of filament residue can block the flow of material, resulting in inconsistent printing. It is advisable to use a small needle or a specialized cleaning filament to unclog nozzles. Additionally, performing a cold pull technique can effectively remove any stubborn blockages without damaging the nozzle.

Next, it’s important to monitor the material used in your 3D printing processes. Ensure that the filament is dry and stored in an appropriate environment. Moisture can lead to issues like bubbling or oozing, which can affect the print quality. Using desiccants or airtight containers can significantly extend the shelf life of the filament. Furthermore, investigate the compatibility of different materials with your printer’s nozzles, especially when switching between filaments, as different compositions may require adjustments in temperature settings or nozzle sizes.

Regularly calibrating the printer is another critical aspect of maintenance. Ensure that the bed is leveled correctly, and the temperatures are set according to the specifications of the material being used. Discrepancies in these settings can lead to first layer adhesion problems or under-extrusion. Lastly, consider establishing a maintenance schedule that includes a complete inspection of the printer. This should involve checking belts, bearings, and other moving parts for wear and tear. By implementing these best practices, users can maximize the efficiency and creativity of their 3 nozzle 3D printers, ultimately leading to enhanced printing outcomes.

Common Challenges and Solutions with 3 Nozzle 3D Printing

3 nozzle 3D printers offer tremendous benefits in terms of efficiency and creativity; however, they also come with their unique set of challenges. Users may frequently encounter issues such as material mixing, calibration problems, and unexpected print failures. Understanding these challenges is essential for optimizing the printing process and maximizing the advantages of multi-nozzle technology.

One of the primary concerns is material mixing. With multiple nozzles, there exists the potential for different materials to unintentionally blend, resulting in compromised print quality. To mitigate this problem, it is crucial to closely monitor the printing process. Implementing appropriate retraction settings can help minimize filament ooze and ensure that only the intended material is extruded. Additionally, experimenting with the sequence in which colors and materials are printed can yield better results. Users can also consider utilizing dedicated nozzles for specific materials, which reduces the chances of cross-contamination.

Calibration is another challenge that 3 nozzle printers often face. Each nozzle must be precisely calibrated to ensure proper alignment and consistent extrusion. A thorough calibration routine should be established, considering the individual filament types being used. Regularly checking the nozzle height and adjusting it as necessary can prevent issues such as improper bed adhesion and print misalignment. Some users find success using automated calibration tools that simplify the calibration process and improve printing accuracy.

Print failures are a common setback in 3D printing that can arise from various factors, including insufficient adhesion, incorrect slicer settings, or mechanical failures. To minimize such failures, users should ensure that the build plate is properly leveled and cleaned. Moreover, optimizing slicer settings, such as layer height and print speed, can lead to enhanced outcomes. When encountering repeated print failures, systematic troubleshooting is essential. Keep a log of adjustments made and the resulting prints to identify recurring issues and develop effective solutions.

Future Trends in Multi-Nozzle 3D Printing Technology

Here are 2 of the best 3d printers on Amazon.

As the landscape of 3D printing technology continues to evolve, multi-nozzle systems, particularly those equipped with three nozzles, are gaining significant attention. These advancements are central to driving efficiency and creativity in various applications. One of the most anticipated innovations in this realm is the increase in print speed. Recent developments have shown that by employing multiple nozzles, manufacturers can significantly reduce the time required to complete complex designs. This boost in speed not only enhances productivity but also allows for rapid prototyping and iterative design processes.

In addition to speed, material versatility stands out as a critical area of focus. The introduction of nozzles that can accommodate different filament types simultaneously enables the creation of more intricate, multi-material prints. This capability is particularly beneficial in industries like aerospace and healthcare, where specialized materials can be used to fabricate parts with varied properties within a single print. Upcoming trends may see even broader compatibility with advanced materials such as composites, flexible filaments, and bio-based solutions, making multi-nozzle printers invaluable assets in many sectors.

Another vital aspect of future developments in three nozzle 3D printing technology is the improvement of software tools designed for enhanced ease of use and sophisticated design capabilities. As the demand grows for user-friendly platforms capable of handling complex designs, the integration of artificial intelligence and machine learning algorithms may revolutionize how users interact with these machines. These tools would facilitate automatic slicing, optimized print settings, and real-time feedback during the printing process. Such innovations would not only streamline operations but also empower creators to experiment and push boundaries further in their projects.

In summary, the future of three nozzle 3D printing looks promising with advancements in print speed, increased material versatility, and enhanced software capabilities paving the way for more efficient and creative manufacturing solutions.

Conclusion: Embracing the 3 Nozzle Revolution

As we reflect on the discussions surrounding 3 nozzle 3D printers, it is evident that their emergence signifies a pivotal shift in the landscape of additive manufacturing. These advanced systems not only enhance efficiency but also expand the creative possibilities for users across various fields, including engineering, design, and educational sectors. With the capability to use multiple materials simultaneously, 3 nozzle 3D printing facilitates complex prints that would be otherwise challenging or impossible with traditional single or dual nozzle systems.

The integration of multi-material capabilities positions 3 nozzle 3D printers as an invaluable tool for professionals and hobbyists alike. Users can experiment with different material properties each nozzle brings, such as varying flexibility, strength, and colors within a single print. Furthermore, this technology allows for the creation of intricate designs, enabling users to push the boundaries of their creativity while optimizing their workflow.

Additionally, the rise of 3 nozzle 3D printing can contribute to sustainability in manufacturing. By reducing waste and enabling more efficient use of materials, it aligns well with contemporary ecological considerations. As industries increasingly prioritize sustainability, embracing this technological advancement becomes a practical choice for those aiming to meet modern manufacturing demands.

In conclusion, the benefits of adopting 3 nozzle 3D printers are substantial, making them a compelling option for individuals and businesses interested in exploring the full spectrum of additive manufacturing. By incorporating this innovative technology, users can maximize their creativity, enhance product quality, and streamline their production processes. As the 3 nozzle revolution continues to evolve, it undoubtedly represents a significant milestone in the journey towards the future of 3D printing.